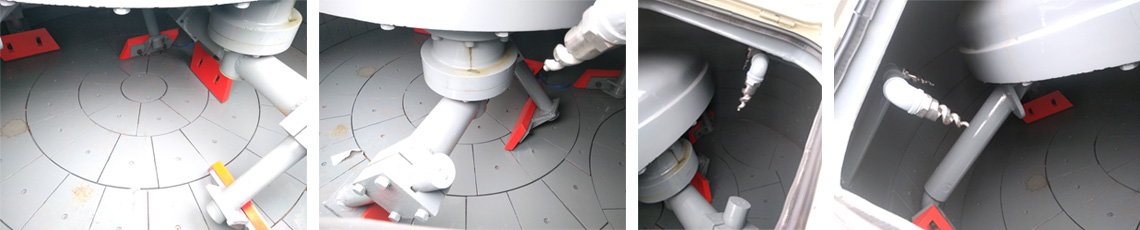

Zhengzhou jianxin vertical axis planetary agitator agitator blades and lining materials can be customized according to the customer's industry.Main materials of

stirrer blades and lining plates in vertical axis planetary agitator:

1. Wear resistant alloy inserts

2. Surfacing welding materials

3. High complex gold

4. Stainless steel materials

5. Ceramic materials

6. Polyurethane material

7. High wear-resistant rubber and cast stone materials

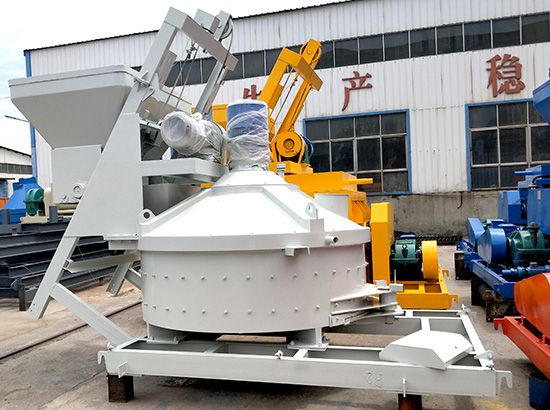

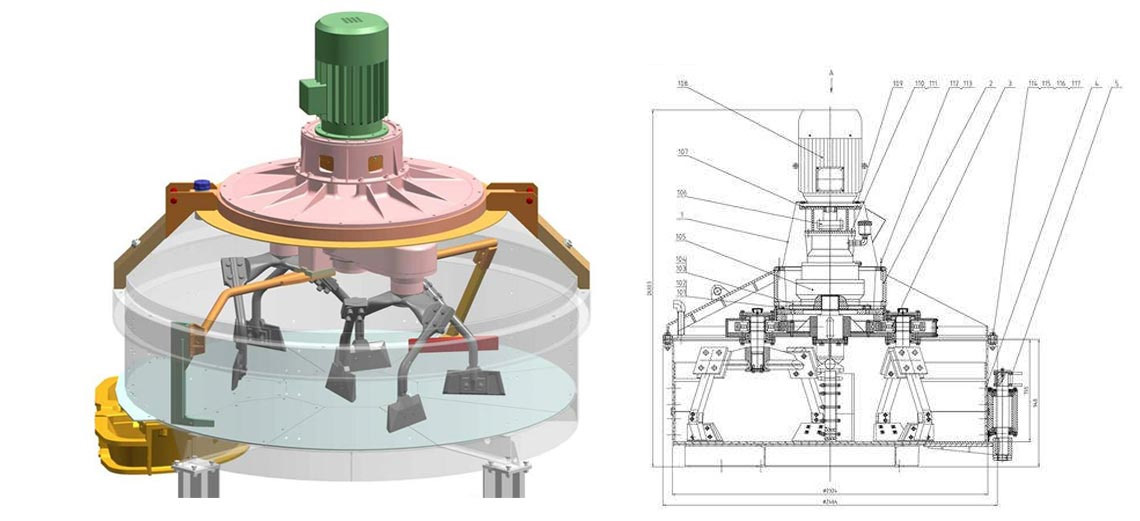

MPC1000 vertical shaft planetary mixer Mixing system

The mixing arm and its blades are planetary-type movements, the mixing trajectory is continuous, the mixing movement is vigorous, and the homogeneity is good; the angle of the stirring blade is reasonable, the mixing efficiency is high, and the wear of the lining plate and the blade is reduced; the bottom squeegee is used for cleaning the bottom material. The side scraper is used to clean the side material and has an automatic cleaning function; the bottom scraper can also increase the unloading speed.

MPC1000 vertical shaft planetary mixer Access door observation port

The large opening of the inspection door is convenient for maintenance; the inspection door is provided with a special sealing strip, and the sealing is reliable; the inspection door has a safety switch, and the main unit is powered off during the switch to ensure safe operation.

The inspection door is provided with an observation port, which can observe the condition of stirring the material during normal operation when the mixer is continuously powered.

MPC1000 vertical shaft planetary mixer Discharging system

The discharging system can be pneumatic or hydraulic. The position and quantity of the discharge door (up to three discharge doors can be opened) can be selected according to the customer's requirements; the discharge door is provided with a special sealing strip and the seal is reliable; the hydraulic pump station has the manual unloading device can manually unload the material in the mixing tank in an emergency.

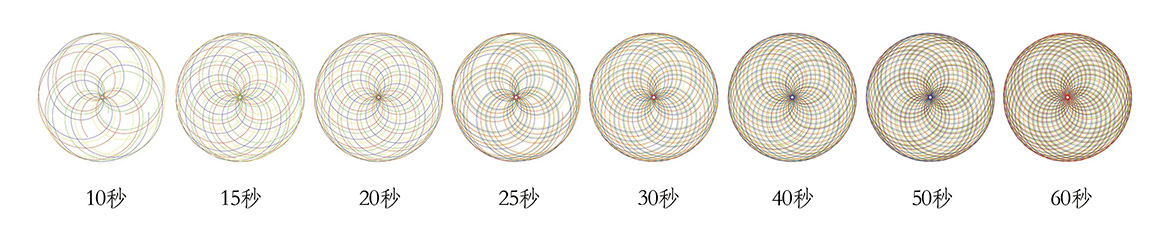

MPC1000 vertical shaft planetary mixer Motion track

The agitating motion trajectory of the vertical axis planetary concrete mixer of Zhengzhou Jianxin Machinery is a non-dead angle trajectory curve with high stirring efficiency and high mixing homogeneity, which is summarized on the basis of years of painstaking research and field test. The rotation of the trajectory of the vertical axis planetary concrete mixer is obtained by superposing the rotation and the revolution of the output agitation. This process belongs to the speed increasing mode, the stirring is fast and labor-saving, and the trajectory curve belongs to the layer progressive and increasingly dense structure. High homogeneity (high mixing uniformity) and high mixing efficiency.

MPC1000 vertical shaft planetary mixer 360° no dead angle stirring

The running track of the mixing arm is more complicated and dense, almost no stirring dead angle, the material is more fully stirred, and the power is strong, the noise is small, and the energy consumption is reduced under the premise of achieving the stirring.

Tel:0086-18437125333/0086-371-86598800

Tel:0086-18437125333/0086-371-86598800

Fax:+86-371-86599393

Fax:+86-371-86599393

E-mail: jianxin@zzjxcorp.com

E-mail: jianxin@zzjxcorp.com

Address:West 200m of Guangwu Road and G310 National Way intersection, Xingyang-Zhengzhou City, Henan Province, 450100 China

Address:West 200m of Guangwu Road and G310 National Way intersection, Xingyang-Zhengzhou City, Henan Province, 450100 China

WeChat:18437125333

Language

Language

Language

Language

Tel:0086-18437125333/0086-371-86598800

Tel:0086-18437125333/0086-371-86598800 Fax:+86-371-86599393

Fax:+86-371-86599393 E-mail: jianxin@zzjxcorp.com

E-mail: jianxin@zzjxcorp.com Address:West 200m of Guangwu Road and G310 National Way intersection, Xingyang-Zhengzhou City, Henan Province, 450100 China

Address:West 200m of Guangwu Road and G310 National Way intersection, Xingyang-Zhengzhou City, Henan Province, 450100 China