JS500 concrete mixer

Field of application: JS500 concrete mixer manufactured by Jianxin Machinery is an advanced and ideal model in domestic and abroad. It has a high degree of automation, good mixing quality, high efficiency, low energy consumption, low noise, easy operation, and fast discharge speed....

WhatsApp:0086-18437125333

Jianxin Brand JS500 concrete mixer is an advanced ideal model which is adopt domestic & international technics.

This mixer has double superiority to do independent operation alone, or form a simple concrete batching plant together with PLD series aggregate batching machine. Also can be used as concrete batching plant's main host.

It's a kind of widely used heigh efficiency mixing machine.

Working principle:

Mixer's brake motor drives the reel by the reducer,the lifting hopper which is pulled by the wire rope through pulley to climbing upward along the loading rack.

When climbing to a certain height, a pair of rollers on the bottom of the lifting hopper door enter the level ramp of the loading rack, the door of the lifting hopper openning automatically, the materials are put into the mixer tank through feeding funnel.

For ensure the hopper can stop in the right place,the limit switches are installed on the top of the loading rack.

There are two limit switches at the upper limit position, which is for limit the lifting hopper's climbing process and safety protection.

There is only one limit switch in the lower limit position. When the hopper descends to the bottom of the pit, the wire rope is slightly loose, the spring lever mechanism makes the lower limit position act, the hoisting mechanisam stops automatically.

The lower limit switch and the spring lever mechanism are all mounted on the top of the upper rail.The upper part of the rack is foldable which is bolted by the bolts. It will be folded when transport for reduce transport height.

JS500 concrete mixer Mixing system

JS500 concrete mixer mixing system consists of electric motor, pulley, reducer, open gear, mixing drum stirring device, oil supply device and other components. During operation, the motor drives the secondary gear reducer. The two shafts of the reducer drive the two horizontal agitating shafts to reverse at the same speed through the two pairs of open gears.

JS500 concrete mixer Feeding system

JS500 concrete mixer feeding system consists of hoisting mechanism, loading frame, hopper, feeding nozzle and other components. The brake motor ensures that the hopper reliably stops at any position during full load operation. The magnitude of the braking torque is adjusted by the large nut of the rear seat of the motor.

JS500 concrete mixer Discharging system

The JS500 concrete mixer discharging system is composed of unloading door, cylinder or hydraulic cylinder and other mechanisms.It has three structures: hydraulic control, pneumatic control, and manual control. The discharge door is installed at the bottom of the mixer, and the motor discharge is realized by a cylinder or a hydraulic cylinder.

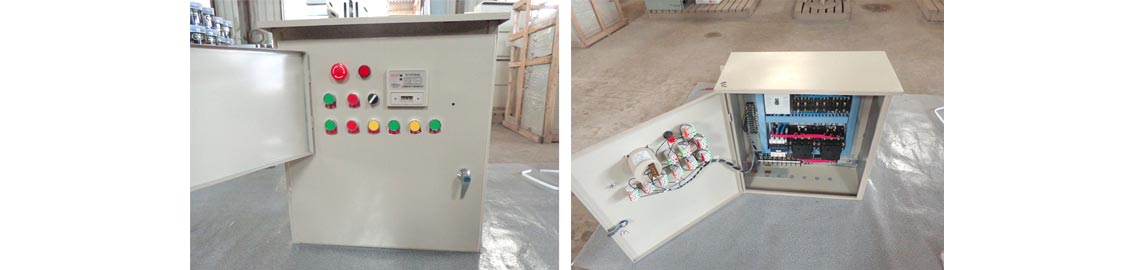

JS500 concrete mixer Electrical System

The electric control circuit of JS500 concrete mixer is equipped with an air switch, a fuse, and a thermal relay, and has the functions of short circuit protection and overload protection. All control buttons and air switch handles and indicators are placed on the distribution box door with a door lock.The electrical components in the distribution box are mounted on a single edge plate, which is safe and reliable, and easy to operate and maintain.

Tel:0086-18437125333/0086-371-86598800

Tel:0086-18437125333/0086-371-86598800

Fax:+86-371-86599393

Fax:+86-371-86599393

E-mail: jianxin@zzjxcorp.com

E-mail: jianxin@zzjxcorp.com

Address:West 200m of Guangwu Road and G310 National Way intersection, Xingyang-Zhengzhou City, Henan Province, 450100 China

Address:West 200m of Guangwu Road and G310 National Way intersection, Xingyang-Zhengzhou City, Henan Province, 450100 China

WeChat:18437125333

Language

Language

Language

Language

Tel:0086-18437125333/0086-371-86598800

Tel:0086-18437125333/0086-371-86598800 Fax:+86-371-86599393

Fax:+86-371-86599393 E-mail: jianxin@zzjxcorp.com

E-mail: jianxin@zzjxcorp.com Address:West 200m of Guangwu Road and G310 National Way intersection, Xingyang-Zhengzhou City, Henan Province, 450100 China

Address:West 200m of Guangwu Road and G310 National Way intersection, Xingyang-Zhengzhou City, Henan Province, 450100 China