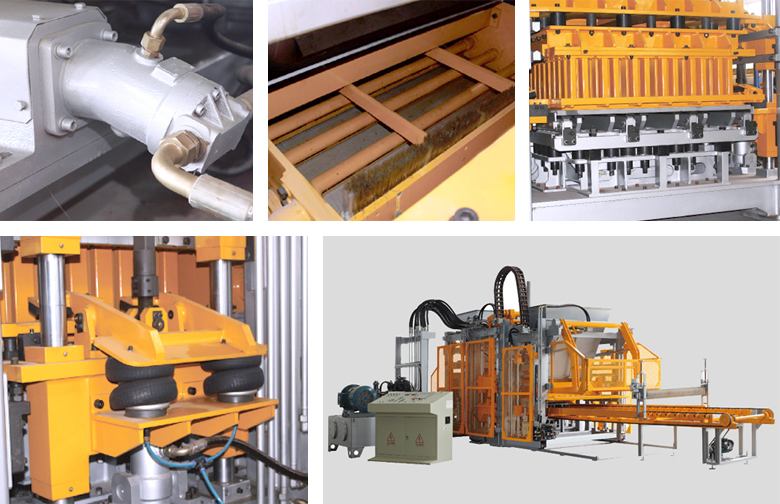

The whole machine: fire free brick machine, electricity, liquid and integrated automatic cycle operation, fault self-diagnosis display, absolute safety performance. Hydraulic: concealed oil circuit reducer takes up space, while shortened tubing makes power more powerful, the main components are used in Germany.

Machine: fire free brick machine set, electricity, liquid and integrated, fully automatic circulation operation, fault self diagnosis shows that

safety performance is absolute.

Hydraulic: The concealed oil road narrowing machine takes up space, while the shortened tubing makes the power more powerful.

The main components are all imported from Germany and the pressure is even greater. It also solves the problem of oil leakage in long-term operation.

Control: Brick machine equipment adopts Japanese Mitsubishi (Germany Siemens) industrial PLC control system, Chinese display, touch operation, stepless frequency change,

change the action at any time according to different raw materials, with great flexibility.

Fabric: unique crank connecting rod structure, forced feeding device, completely solve the problem of special-shaped brick fabrics, secondary fabrics can produce a variety of

colored pavement bricks.

Mould: increase the thickness, fine grinding, special steel, high-frequency carburizing treatment, mold box buckle plate without welding, longer life.

With a cartridge-style design, it can be replaced in a matter of minutes to achieve multiple uses.

Tel:0086-18437125333/0086-371-86598800

Tel:0086-18437125333/0086-371-86598800

Fax:+86-371-86599393

Fax:+86-371-86599393

E-mail: jianxin@zzjxcorp.com

E-mail: jianxin@zzjxcorp.com

Address:West 200m of Guangwu Road and G310 National Way intersection, Xingyang-Zhengzhou City, Henan Province, 450100 China

Address:West 200m of Guangwu Road and G310 National Way intersection, Xingyang-Zhengzhou City, Henan Province, 450100 China

WeChat:18437125333

Language

Language

Language

Language

Tel:0086-18437125333/0086-371-86598800

Tel:0086-18437125333/0086-371-86598800 Fax:+86-371-86599393

Fax:+86-371-86599393 E-mail: jianxin@zzjxcorp.com

E-mail: jianxin@zzjxcorp.com Address:West 200m of Guangwu Road and G310 National Way intersection, Xingyang-Zhengzhou City, Henan Province, 450100 China

Address:West 200m of Guangwu Road and G310 National Way intersection, Xingyang-Zhengzhou City, Henan Province, 450100 China