Language

Language

Language

Language

Molding cycle: 12-25s

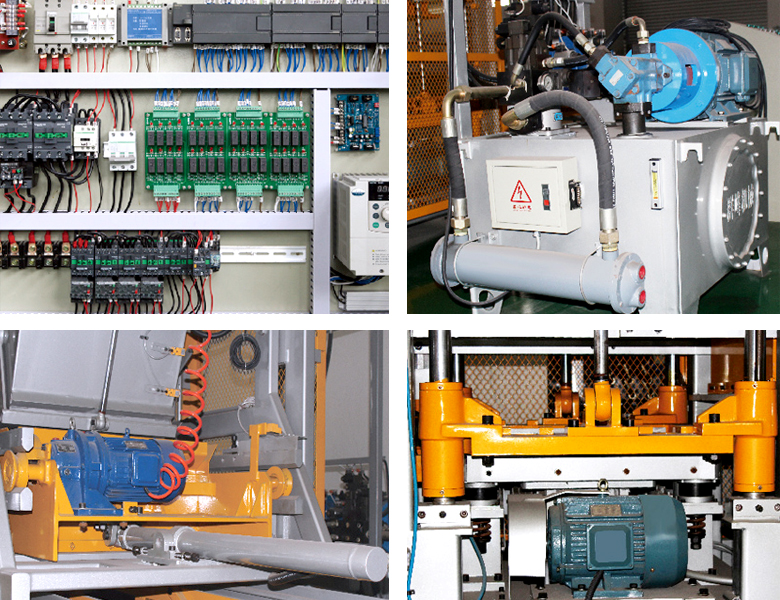

Total power: 37.5kW

Equipment model: QT6-15

| Mainframe size | 3270×1850×3200mm |

| Rated pressure | 21MPa |

| Main mode of vibration | Platform vibration |

| Vibration frequency | 1500-4100 times / minute |

| Pallet size | 850×680mm |

| Molding cycle | 12-25s |

| Total power | 37.5kW |

| Mainframe size | 3270×1850×3200mm |

| Rated pressure | 21MPa |

| Main mode of vibration | Platform vibration |

| Vibration frequency | 1500-4100 times / minute |

| Pallet size | 850×680mm |

| Molding cycle | 12-25s |

| Total power | 37.5kW |

Tel:0086-18437125333/0086-371-86598800

Tel:0086-18437125333/0086-371-86598800

Fax:+86-371-86599393

Fax:+86-371-86599393

E-mail: jianxin@zzjxcorp.com

E-mail: jianxin@zzjxcorp.com

Address:West 200m of Guangwu Road and G310 National Way intersection, Xingyang-Zhengzhou City, Henan Province, 450100 China

Address:West 200m of Guangwu Road and G310 National Way intersection, Xingyang-Zhengzhou City, Henan Province, 450100 China

WeChat:18437125333